How To Choose The Best Urethane Blade For Your Belt Cleaner: Lab Test Results Revealed

When I wrote a blog post recently outlining why tungsten carbide blades were used on belt cleaners, I knew the very next question readers would have would be “what about urethane blades?” and I was right. So here it is! Read on to discover what urethane blades are, when urethane blades are used on belt cleaners, and how to choose the right one. Somewhere along the line, I even reveal independent lab test results on the performance of common urethane blades in the market.

Polyurethane—or urethane—is a combination of two chemical compounds. It was first developed as a replacement for rubber at the beginning of World War II. By changing the component ingredients in the urethane formula and varying the durometer—or hardness—of the product, urethane has been a material of choice for conveyor belt cleaner blades.

Are all urethane blades the same?

Are all urethane blades the same?

Most definitely not! The type of raw materials and the “pour,” or the way the compounds are formulated, all affect the blade’s effectiveness.

Errors during the pour, including incorrect mixing ratios, mold release contamination, humidity, and the process temperature all influence the qualities of the urethane and the resulting characteristics of the blades made from that urethane.

The proprietary formulation Flexco uses ensures a urethane with an optimal durometer rating to provide efficient cleaning, as well as abrasion resistance that adds significantly to the wear life – even in demanding applications – while still remaining compatible with belt splices.

Also, independent testing has shown that a urethane formulated specifically for superior abrasion resistance offers 25 to 35% longer wear life compared to other formulations.

What should you look for in a urethane blade?

What should you look for in a urethane blade?

When choosing a urethane blade, I recommend looking for blades that offer four things:

- Best-in-class cleaning efficiency. When optimally tensioned, a urethane blade will provide excellent cleaning, while still being a little easier on the belt than a tungsten blade.

- Good value. Urethane blades are often a more economical blade choice. Regardless, it’s still important to choose a blade that is going to offer you good value when it comes to considering lifetime cost vs. initial cost.

- Compatibility. Urethane is highly compatible with mechanical splices used on conveyor belts. When encountering a mechanical splice during operation, urethane blades are forgiving. The splice is not damaged and the blade provides efficient cleaning performance.

- Versatility. There are many applications that require specialty formulations, such as high heat, chemical resistance, or water removal. Make sure you select the right urethane blade for your application.

Where to use urethane blades

Urethane blades can be used in many different applications and industries. If you are considering whether urethane is the right option for you, think about using urethane blades in the following situations:

- When your belt is mechanically fastened. A mechanically fastened belt is an ideal application for a urethane blade that offers complete compatibility with mechanical splices. The urethane blade should glide over the splice and sacrifice itself to protect the splice if needed, all with minimal cleaning disruption. Note: Flexco tungsten carbide C-Tip blades can be used with mechanically fastened belts, you can read more about those here.

- When using with highly abrasive materials. Urethane blades are a good choice for when you are conveying abrasive materials on your belt line as they offer greater wear life.

- On your primary belt cleaners. Traditionally urethane blades have been used in primary cleaner applications – specifically on the head pulley – where the belt is held flat and has little opportunity to “give” should a problem arise. For example, this precleaner, or this precleaner are both excellent primary cleaning options.

On your secondary belt cleaners. They can also be used effectively in secondary cleaner applications as they are especially good at removing fines, increasing over cleaning efficiency up to 90 percent. For example, this secondary belt cleaner offers excellent cleaning efficiency and also reduces time spent on maintenance, as this real life story describes in a sand and gravel plant.

High-performance polyurethane blades

High-performance polyurethane blades

Manufacturing a high-performing polyurethane blade isn’t as easy as it may seem. It took our engineering team extensive laboratory and field testing to identify several properties that help determine how well a polyurethane blade will perform in real-world applications.

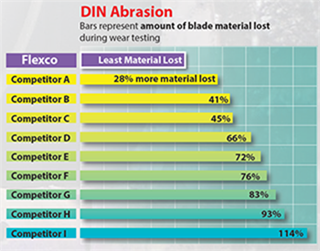

DIN Abrasion: The DIN Abrasion test can be used to determine the wear rate of urethane formulations. Blade samples with less material loss after a DIN test have a lower score, indicating longer predicted wear life. While this laboratory test is not the singular factor in predicting blade life, it is a leading indicator of what to expect in operation. Other factors such as durometer, tensile strength, and elongation also play a role.

As part of our ongoing research and goal to provide the highest-performing blades on the market, our team compared 10 U.S. and global urethane blade manufacturers on DIN abrasion. These lab tests are conducted in Flexco’s research facility and independently run and verified by Akron Development Labs.

As you can see in the table to the right, the results show that Flexco has the least amount of urethane material abrading away during the test. This means that by using the Flexco urethane blade formulation, you can expect longer wear life versus other urethane options in the market. Less maintenance and longer life sounds good, right?

Speaking of longer life

Speaking of longer life

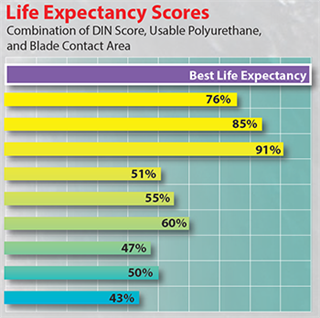

When belt cleaners are installed and tensioned correctly, there are a few factors that contribute to the overall life expectancy of a blade. The quality of the urethane is one of the leading factors. And as I noted with the DIN abrasion results above, not all urethanes are created equal. Another key factor is the amount of usable urethane and how the blade contacts the belt.

Analysis of all of these elements allows for an estimation of relative life expectancies of Flexco’s ConShear™ blade versus comparable competitive products in the industry. In the table to the right, life expectancy is not measured as an estimate of time, but a percentage relative to other samples. The superior abrasion resistance and blade volume, combined with the patented faceted blade profile, points to an industry-leading life expectancy.

Types of urethane blades

Flexco’s polyurethane blades are produced in our Grand Rapids, MI facility. Our polyurethanes were developed following testing on more than 100 various formulas to identify the best solutions to the widest range of applications.

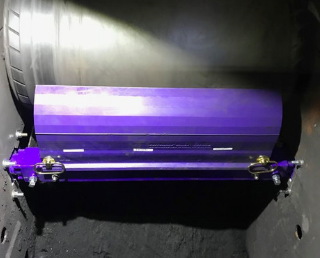

The standard purple formulation is ideal for most standard applications and has years of proven, unmatched success in applications such as aggregate, coal, iron ore, copper, and many more.

The yellow, high-temperature formulation addresses applications in clinker, cement, asphalt, and coke, among other high-temp applications up to 275F/135C. Its higher durometer also lends itself to improved performance in high-tonnage and/or heavy, wet, or muddy applications.

The red, ultra-high temperature formulation goes one step further with temperature resistance up to 400F/200C. It is great for exceptionally hot applications in clinker, coke, or others. This may also be used in applications that run empty belts for prolonged periods of time which may create friction-related heat build-up.

The blue, FRAS (Fire Resistant Anti-Static) formula is designed specifically for use in explosive environments and is used in our ATEX-certified cleaner assemblies.

Lastly, the white formulation, made from chemical-resistant and FDA-approved materials, is ideal in applications containing fermentation byproducts or pre-processed foods, such as sugar. All of these formulations are available in a variety of formats to suit each individual application.

Improving belt cleaner importance

It’s important for us to continue to enhance belt cleaner performance to minimize downtime and provide a greater return on your investment. We utilize independent test labs, a Flexco-based test lab, internally controlled conveyor systems, and most importantly, field-proven results to verify that the advancements we make lead to improved cleaning performance and blade life. If you have any questions, I’d like to hear them! You can ask us anything on our social media accounts. Click the icons at the bottom of this page to get in touch.

Authored by: Kevin Fales, Product Manager

Fales manages the belt conveyor product (BCP) line, providing product development and engineering with guidance on market requirements for both new product concepts and existing products. He also leads the development of technical and promotional literature supporting BCP line. Fales graduated from Grand Valley State University with a bachelor’s degree in Marketing and is currently working toward his master’s degree in business administration from Western Michigan University.

Subscribe to the Flexco Blog

Related Blogs

Published Date

November 15, 2018Product Group

- Belt Cleaning Systems

Issues

- Blade Life

- Carryback

- Downtime